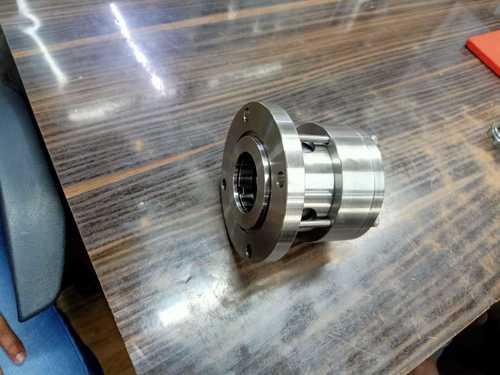

Mechanical Ceramic Seals

Price 400 INR/ Piece

Mechanical Ceramic Seals Specification

- Tolerance

- 0.01 mm

- Style

- Mechanical Seal Ring

- Shape

- Round

- Application

- Pumps, Compressors, Agitators

- Color

- White

- Customization

- Available on request

- Flexural Strength

- 300 MPa

- Thermal Conductivity

- 20 W/mK

- Standard Size Range

- 12 mm 80 mm (OD)

- Density

- 3.8 g/cm

- Corrosion Resistance

- Excellent against acids and alkalies

- Surface Finish

- Polished

- Maximum Pressure

- Up to 2 MPa

- Water Absorption

- <0.02%

Mechanical Ceramic Seals Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 2-5 Days

About Mechanical Ceramic Seals

In our extensive range of products, we also offer our esteemed clients a wide assortment of high quality Ceramic Seals. Manufactured using quality ceramic and advanced methodology, these seals are widely demanded in the market. The offered seals are strictly tested on various quality parameters in terms of durability and strength. Further, these Ceramic Seals are available with us in various specifications to fulfill the diverse requirements of our trust-worthy clients.

Superior Corrosion Resistance in Aggressive Environments

Engineered to withstand acidic and alkaline media, these mechanical ceramic seals provide outstanding longevity and performance in environments where corrosion is a significant concern. The polished finish and advanced material formulation ensure that the seals maintain their integrity, making them ideal for demanding industrial applications in chemical processing, water treatment, and more.

Precision Engineering and Broad Applications

With a dimensional tolerance of 0.01 mm and available outer diameters from 12 mm to 80 mm, these ceramic seal rings are suitable for use in pumps, compressors, and agitators. Their robust flexural strength and low water absorption further enable reliable operation in critical mechanical assemblies, offering versatility and confidence for engineers and end-users alike across India.

FAQs of Mechanical Ceramic Seals:

Q: How do mechanical ceramic seals withstand high-pressure and corrosive environments?

A: Mechanical ceramic seals are crafted using advanced white ceramic with a polished finish, offering resistance to pressures up to 2 MPa. Their excellent corrosion resistance against acids and alkalies ensures durability and optimal performance in chemically aggressive settings, making them suitable for a variety of industrial applications.Q: What is the process of customizing ceramic seal rings for specific pump or compressor applications?

A: Customization starts with specifying your required outer diameter, shape, and any unique tolerance needs. Provide the application details, and manufacturers or suppliers in India will tailor the seal rings to precise dimensions and performance characteristics, ensuring compatibility with your equipment.Q: When should I choose a mechanical ceramic seal over other sealing solutions?

A: Opt for a mechanical ceramic seal when your system operates under harsh chemical conditions, demands high durability, or needs high-precision sealing with low water absorption. Their superior flexural strength and corrosion resistance make them a smart choice for pumps, compressors, and agitators handling aggressive fluids.Q: Where can I purchase these ceramic mechanical seals in standard or custom sizes in India?

A: These seals are readily available through distributors, manufacturers, suppliers, and wholesalers across India. You can order standard sizes ranging from 12 mm to 80 mm OD or request custom dimensions to match your systems requirements.Q: What are the main benefits of using these ceramic mechanical seals in industrial applications?

A: The key benefits include exceptional chemical stability, high pressure resistance, superior mechanical strength, and minimal water absorption. These features enhance equipment reliability and reduce maintenance, especially in pumping and agitating systems exposed to challenging fluids.Q: How should these ceramic seals be installed to ensure optimal performance?

A: Carefully align the mechanical seal ring with the mating component and ensure cleanliness during installation to avoid introducing any debris. Follow equipment guidelines for torque settings and handling, as the precise 0.01 mm tolerance aids in achieving a leak-tight, stable seal.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Shaft Seals Category

CHOPPER & MAIN SHAFT SEAL FOR RMG

Price 3500 INR / Piece

Minimum Order Quantity : 10 Pieces

Style : Other, Rotary Shaft Seal

Tolerance : 0.05 mm

Temperature : 30C to +110C

Shape : Round

Grundfos Pump Seal

Price 1000 INR / Piece

Minimum Order Quantity : 10 Pieces

Style : Mechanical Seal

Tolerance : 0.05 mm

Temperature : 20C to 180C

Shape : Round

Multi Spring Seal

Price 3500 INR / Piece

Minimum Order Quantity : 10 Pieces

Style : Mechanical Seal

Tolerance : 0.05 mm

Temperature : 20C to 200C

Shape : Round

SINGLE CARTRIDGE WITH BEARING SEAL

Price 1000 INR / Piece

Minimum Order Quantity : 10 Pieces

Style : Other, Single Cartridge

Tolerance : 0.01 mm

Temperature : 20C to 180C

Shape : Round

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS