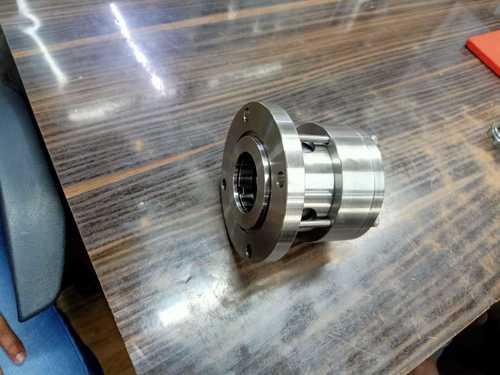

CHOPPER & MAIN SHAFT SEAL FOR RMG

Price 3500 INR/ Piece

CHOPPER & MAIN SHAFT SEAL FOR RMG Specification

- Feature

- Oil & chemical resistant, anti-abrasive, long service life

- Tolerance

- 0.05 mm

- Hardness

- 60-70 Shore A

- Material

- Nitrile Rubber (NBR)

- Style

- Rotary Shaft Seal

- Shape

- Round

- Temperature

- -30C to +110C

- Application

- Rapid Mixer Granulator (RMG) Main/Chopper Shaft

- Surface Finish

- Smooth, precision moulded

- Installation Method

- Press fit into housing

- Diameter Range

- 10 mm to 80 mm (custom sizes available)

- Color

- Black

- Pressure Resistance

- Up to 5 bar

- Compliance

- FDA compliant rubber

- Seal Type

- Double Lip with Spring

CHOPPER & MAIN SHAFT SEAL FOR RMG Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 2-5 Days

About CHOPPER & MAIN SHAFT SEAL FOR RMG

Key Application & Superior Advantages

Used as a critical sealing solution in Rapid Mixer Granulator (RMG) main and chopper shafts, this seal stands out for its monumental durability, ensuring excellent protection against leakage and contamination. Its precision moulded, smooth surface finish guarantees optimal compatibility with rotary shafts, elevating operational efficiency. Primary competitive advantages include FDA compliance, oil and chemical resistance, and readiness for custom sizing, making it ideal for pharmaceuticals and allied industries.

Delivery & Supply Assurance

Our seals are dispatched rapidly to maximise your productivity and minimise downtime. Depend on secure shipping methods to safeguard your expenditure throughout the supply chain. With outstanding supply ability and readiness for bulk orders, we serve distributers, manufacturers, suppliers, and wholesalers. The FOB port option ensures flexible logistics and timely deliveries across India, catering to urgent requirements with streamlined processes.

FAQs of CHOPPER & MAIN SHAFT SEAL FOR RMG:

Q: How is the Chopper & Main Shaft Seal for RMG installed?

A: The seal is designed for press-fit installation directly into the housing of the rapid mixer granulators main or chopper shaft, allowing for quick and secure setup.Q: What benefits does the double lip with spring design offer?

A: This design, featuring a double lip and integrated spring, provides excellent sealing efficiency and improved resistance to pressure, oil, and chemicals, extending the seals service life.Q: Where can custom-sized seals be sourced for unique diameter requirements?

A: Custom sizes ranging from 10 mm to 80 mm can be requested directly from the distributor, manufacturer, supplier, or wholesaler, ensuring compatibility with specific RMG models.Q: What is the process for placing an order and securing delivery?

A: Orders can be placed through authorised channels. After order confirmation, products are securely shipped via FOB port. The robust supply network ensures quick dispatch and delivery throughout India.Q: When should the seal be replaced during RMG maintenance routines?

A: Replacement intervals depend on operating conditions, but seals should be inspected regularly and replaced at the first sign of wear or reduced sealing performance to preserve mixing quality and prevent leaks.Q: How does the FDA-compliant nitrile rubber benefit pharmaceutical applications?

A: FDA-compliant nitrile rubber ensures that the seal meets health and safety regulations, providing confidence for pharmaceutical mixing processes where contamination control is paramount.Q: What ensures the longevity of the Chopper & Main Shaft Seal for RMG?

A: Monumental durability is achieved through anti-abrasive properties, oil and chemical resistance, precise tolerances, and robust material quality, making it well suited for heavy-duty, continuous use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Shaft Seals Category

Grundfos Pump Seal

Price 1000 INR / Piece

Minimum Order Quantity : 10 Pieces

Shape : Round

Tolerance : 0.05 mm

Application : Grundfos Pump, Industrial, Chemical, Water Treatment

Style : Mechanical Seal

SINGLE CARTRIDGE WITH BEARING SEAL

Price 1000 INR / Piece

Minimum Order Quantity : 10 Pieces

Shape : Round

Tolerance : 0.01 mm

Application : Pumps, Mixers, Compressors

Style : Other, Single Cartridge

DRY CARTRIDGE SEAL

Price 17000 INR / Piece

Minimum Order Quantity : 10 Pieces

Shape : Round

Tolerance : 0.02 mm

Application : Pumps, Mixers, Agitators

Style : Other, Cartridge

Slurry Seals

Price 1500 INR / Piece

Minimum Order Quantity : 10 Pieces

Shape : Round

Tolerance : 0.05 mm

Application : Slurry Transfer Pumps, Mineral Processing, Chemical Handling

Style : Other, Balanced and Unbalanced

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS