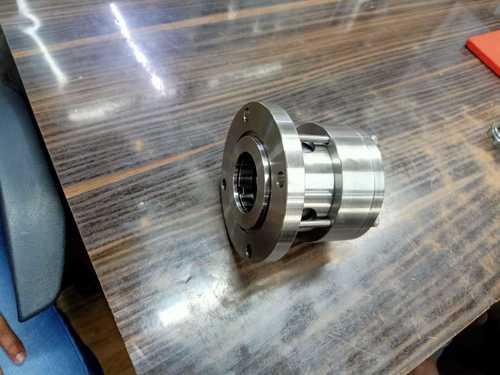

SINGLE CARTRIDGE WITH BEARING SEAL

Price 1000 INR/ Piece

SINGLE CARTRIDGE WITH BEARING SEAL Specification

- Tolerance

- 0.01 mm

- Hardness

- 60-70 HRC

- Material

- Stainless Steel / Carbon Graphite

- Style

- Single Cartridge

- Shape

- Round

- Temperature

- -20C to 180C

- Application

- Pumps, Mixers, Compressors

- Rotational Speed

- Up to 3500 RPM

- Shaft Diameter Range

- 25 mm to 100 mm

- Compliance

- ISO 3069, API 682

- Finish

- Machined & Polished

- Installation

- Easy, Plug-in Cartridge

- Lubrication

- Grease/Liquid lubricated

- Leakage

- Zero or Minimal

- Seal Type

- Bearing Seal

- Corrosion Resistance

- High

- Pressure Rating

- Up to 25 bar

SINGLE CARTRIDGE WITH BEARING SEAL Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 2-5 Days

About SINGLE CARTRIDGE WITH BEARING SEAL

Engineered for Optimal Performance

The Single Cartridge with Bearing Seal is meticulously crafted for high-efficiency sealing in pumps, mixers, and compressors. Its advanced design supports pressure up to 25 bar and speeds up to 3500 RPM, making it suitable for diverse industrial applications. The seals round, machined, and polished finish, combined with a corrosion-resistant construction, assures reliability and durability even in severe conditions.

Easy Installation and Maintenance

Featuring a user-friendly plug-in cartridge design, this bearing seal allows for quick installation and straightforward replacement. The seals standardized shaft diameter range of 25 mm to 100 mm ensures compatibility with various equipment. Lubrication options include grease or liquid, optimizing its fit for your operational needs and increasing its service life.

Robust Compliance and Materials

Manufactured using high-grade stainless steel or carbon graphite, the seal complies with rigorous ISO 3069 and API 682 standards. With a hardness rating of 6070 HRC and tight tolerances of 0.01 mm, it delivers reliable, leak-minimal performance and exceptional durability. The machined and polished finish ensures smooth operation and reduces the risk of operational issues.

FAQs of SINGLE CARTRIDGE WITH BEARING SEAL:

Q: How is the Single Cartridge with Bearing Seal installed?

A: This bearing seal features a plug-in cartridge design, enabling straightforward installation without intensive equipment or specialized tools. Simply align and insert the cartridge into its designated slot on the shaft, minimizing installation time and ensuring a secure fit.Q: What benefits does the bearing seal offer over traditional sealing solutions?

A: Compared to conventional seals, this bearing seal provides high corrosion resistance, minimal or zero leakage, high operational reliability, and effortless installation. Its compliance with leading international standards further assures consistent and safe performance in industrial environments.Q: When should I use grease or liquid as a lubricant for this seal?

A: Choose grease lubrication for applications requiring infrequent maintenance or operating at lower temperatures, while liquid lubrication is preferable for high-speed or high-temperature environments to ensure optimal seal longevity and performance.Q: Where can the Single Cartridge with Bearing Seal be applied?

A: It is ideal for use in pumps, mixers, and compressors across industries such as chemical processing, water treatment, food and beverage, and pharmaceuticals, thanks to its wide temperature and shaft diameter range.Q: What is the operating temperature range of this bearing seal?

A: The seal is designed to function efficiently in temperatures ranging from -20C to 180C, covering a broad array of operational requirements in demanding applications.Q: How does the seal achieve zero or minimal leakage?

A: With its precision engineering, tight tolerance of 0.01 mm, and advanced material choices, the seal ensures a secure interface with rotating shafts, effectively preventing leaks even under high-pressure conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Shaft Seals Category

Multi Spring Seal

Price 3500 INR / Piece

Minimum Order Quantity : 10 Pieces

Shape : Round

Application : Pumps, Compressors, Mixers, Agitators

Style : Mechanical Seal

Material : SS304, SS316, Carbon, Ceramic, Silicon, Viton, PTFE

Mechanical Ceramic Seal Rings

Price 400 INR / Piece

Minimum Order Quantity : 10 Pieces

Shape : Round

Application : Mechanical seals for pumps, compressors, agitators, and mixers

Style : Other, Ring

Slurry Seals

Price 1500 INR / Piece

Minimum Order Quantity : 10 Pieces

Shape : Round

Application : Slurry Transfer Pumps, Mineral Processing, Chemical Handling

Style : Other, Balanced and Unbalanced

Material : Carbon, Silicon Carbide, Ceramic, Tungsten Carbide, Rubber, PTFE

Mechanical Reactor Seals

Price 4200 INR / Piece

Minimum Order Quantity : 1 , , Piece

Shape : Round (Standard Reactor Seal Configuration)

Application : Chemical reactors, pharmaceuticals, petrochemicals, and agitators

Style : Other, Cartridge, Double, Single, Balanced/Unbalanced

Material : SS316, Carbon, Silicon Carbide, Ceramic, PTFE, Alloy 20

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS