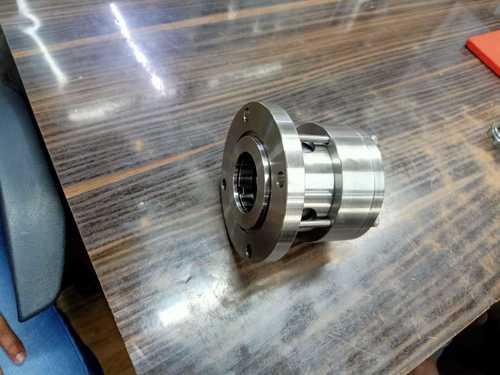

Slurry Seals

Price 1500 INR/ Piece

Slurry Seals Specification

- Tolerance

- 0.05 mm

- Material

- Carbon, Silicon Carbide, Ceramic, Tungsten Carbide, Rubber, PTFE

- Style

- Balanced and Unbalanced

- Shape

- Round

- Application

- Slurry Transfer Pumps, Mineral Processing, Chemical Handling

- Mounting

- Easy to Install

- Corrosion Resistance

- High

- Shaft Size Range

- 20 mm to 100 mm

- Color

- Black/Metallic Grey

- Speed

- Up to 5000 RPM

- Sealing Type

- Single and Double Acting

- Abrasion Resistance

- Excellent

- Pressure Rating

- Up to 25 bar

- Leakage

- Minimal to zero

- Compliance

- API 682, ISO 3069

Slurry Seals Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 2-5 Days

About Slurry Seals

Fostered with a team of highly experienced professionals, we are able to manufacture and supply an assortment of Slurry Seals. The offered seals are manufactured using superior grade raw materials and latest technology in accordance with set industry guidelines. Further, this mechanical shaft seal is polished with corrosion resistant paint that ensures its durability. Widely renowned for their sturdy construction, durable finish and easy installation, these Slurry Seals are tested on various quality parameters for ensuring their optimum quality.

Superior Performance in Challenging Applications

Slurry Seals are specifically designed to deliver reliable sealing in harsh slurry environments. Their high abrasion and corrosion resistance ensure longevity and consistent performance, even in mineral processing and chemical handling industries. Equipped with advanced materials and minimal leakage, they maintain operational continuity and reduce maintenance requirements.

Versatile and Compliant Design

With a wide shaft size range, support for both balanced and unbalanced configurations, and compliance to strict standards like API 682 and ISO 3069, these seals suit a variety of pumps and systems. Their ease of installation and precise tolerance provide added convenience and compatibility, ensuring a seamless fit for OEMs, suppliers, and plant operators alike.

FAQs of Slurry Seals:

Q: How do slurry seals handle abrasive and corrosive environments?

A: Slurry seals incorporate robust materials such as silicon carbide, tungsten carbide, ceramic, and PTFE, providing high resistance to abrasion and corrosion. This makes them especially suitable for processes involving aggressive slurries and chemicals.Q: What is the installation process for these slurry seals?

A: Designed with user convenience in mind, these seals feature easy mounting. They can be installed on shafts ranging from 20 mm to 100 mm and come with straightforward instructions, minimizing downtime during setup.Q: When should I choose a single acting versus a double acting seal?

A: Single acting seals are ideal for less demanding applications with lower pressure or cleaner media, while double acting seals are recommended for high-pressure, hazardous, or particularly abrasive slurries where added protection and leak prevention are required.Q: Where can these slurry seals be used effectively?

A: These seals are perfect for slurry transfer pumps, mineral processing operations, and chemical handling plants. Their robust design and material choices ensure reliable service in various industrial applications across India.Q: What are the main benefits of using these seals in industrial pumps?

A: The primary benefits include minimal to zero leakage, long service life due to excellent abrasion and corrosion resistance, easy installation, and reliable performance at high pressures up to 25 bar and speeds up to 5000 RPM.Q: How do these seals ensure compliance and safety?

A: Each slurry seal is manufactured according to API 682 and ISO 3069 standards, ensuring operational safety, reliability, and compatibility with global industry requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Shaft Seals Category

CHOPPER & MAIN SHAFT SEAL FOR RMG

Price 3500 INR / Piece

Minimum Order Quantity : 10 Pieces

Shape : Round

Tolerance : 0.05 mm

Style : Other, Rotary Shaft Seal

Application : Rapid Mixer Granulator (RMG) Main/Chopper Shaft

Grundfos Pump Seal

Price 1000 INR / Piece

Minimum Order Quantity : 10 Pieces

Shape : Round

Tolerance : 0.05 mm

Style : Mechanical Seal

Application : Grundfos Pump, Industrial, Chemical, Water Treatment

SINGLE CARTRIDGE WITH BEARING SEAL

Price 1000 INR / Piece

Minimum Order Quantity : 10 Pieces

Shape : Round

Tolerance : 0.01 mm

Style : Other, Single Cartridge

Application : Pumps, Mixers, Compressors

Mechanical Ceramic Seals

Price 400 INR / Piece

Minimum Order Quantity : 10 Pieces

Shape : Round

Tolerance : 0.01 mm

Style : Other, Mechanical Seal Ring

Application : Pumps, Compressors, Agitators

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS