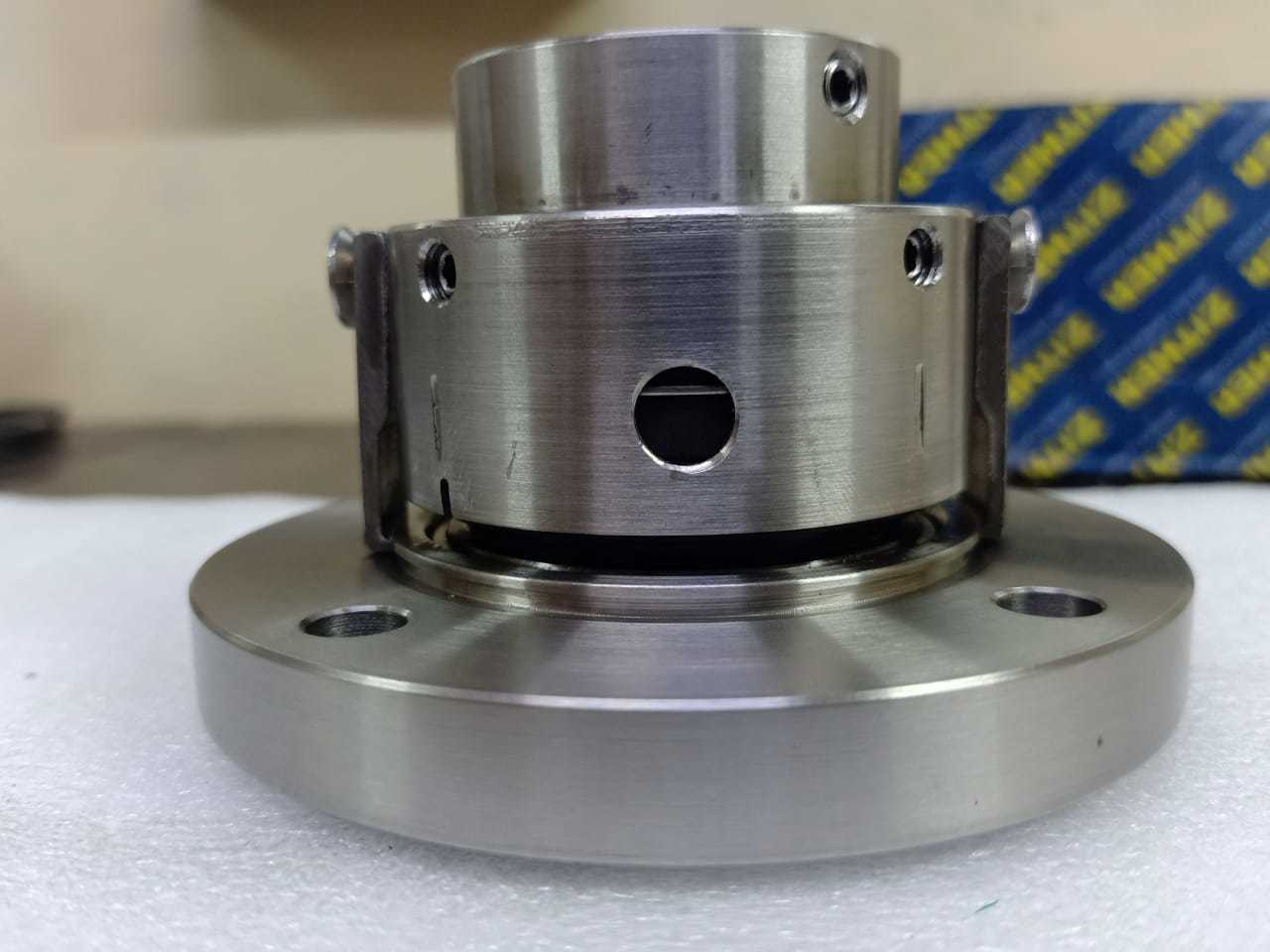

DRY CARTRIDGE SEAL

Price 17000 INR/ Piece

DRY CARTRIDGE SEAL Specification

- Tolerance

- 0.02 mm

- Material

- Carbon, Silicon Carbide, SS316, EPDM, Viton

- Style

- Cartridge

- Shape

- Round

- Application

- Pumps, Mixers, Agitators

- Mounting

- Easy to install and remove

- Spring Type

- Multi Spring

- Standards

- API 682 / EN 12756

- Usage Environment

- Corrosive and abrasive media

- Size Range

- 25 mm to 100 mm shaft size

- Speed

- Up to 20 m/s

- Seal Face Combination

- Carbon vs Silicon Carbide / Silicon Carbide vs Silicon Carbide

- Pressure

- Up to 25 bar

DRY CARTRIDGE SEAL Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 2-5 Days

About DRY CARTRIDGE SEAL

Our rich industrial experience enables us to manufacture and supply broad an array of Industrial Seals. These seals are used in various equipment for a leak proof seal which ensures tight sealing of liquids. Designed by experts using high quality raw materials with precision, these seals are available in different diameters and thicknesses. The offered seals are known for hardness, high tensile strength, accurate dimensions and durability. Also, we ensure our clients that these Industrial Seals are tested on various quality parameters, which ensures their reliability.

Precision Engineering for Demanding Applications

The dry cartridge seal is specifically crafted for challenging industrial environments, providing a robust solution in handling both corrosive and abrasive media. Its engineered tolerance of 0.02 mm ensures a precise fit, minimizing leakage and operational downtime. This seal can accommodate a wide range of pump, mixer, and agitator applications across the chemical, petrochemical, and food processing sectors.

Durable Materials for Extended Seal Life

Constructed from premium materials such as Carbon, Silicon Carbide, SS316, EPDM, and Viton, the dry cartridge seal meets high standards for strength and chemical resistance. These components allow the seal to reliably handle aggressive fluids while extending its operational lifespan, thereby reducing maintenance demands and related costs.

FAQs of DRY CARTRIDGE SEAL:

Q: How is the dry cartridge seal installed and removed?

A: The dry cartridge seal is designed for easy installation and removal, featuring a user-friendly mounting style. It can be placed on the shaft and secured following standard procedures, greatly reducing downtime during maintenance or replacement.Q: What types of applications is this seal suitable for?

A: This seal is ideal for use in pumps, mixers, and agitators that operate in environments containing corrosive or abrasive media. It is commonly utilized in chemical processing, water treatment, and other industries requiring robust sealing solutions.Q: When should a dry cartridge seal be chosen over other seal types?

A: A dry cartridge seal is recommended when you need a low-maintenance, high-performance solution capable of withstanding high pressure (up to 25 bar), fast speeds (up to 20 m/s), and harsh substances. Its compatibility with API 682 and EN 12756 standards also makes it suitable for regulated environments.Q: Where can the dry cartridge seal be used?

A: This product is versatile and can be installed in industrial machinery across sectors such as petrochemical, pharmaceutical, mining, and water treatment facilities throughout India and globally.Q: What benefits does the multi spring design provide?

A: The multi spring design ensures consistent face loading and improved sealing efficiency. This results in reliable operation under varying pressures, while also enhancing the seals service lifespan even in abrasive or corrosive conditions.Q: How does the choice of seal face combination impact performance?

A: Selecting from Carbon vs Silicon Carbide or Silicon Carbide vs Silicon Carbide allows users to address specific compatibility and durability requirements. The right combination can improve resistance to wear and chemical attack, optimizing seal longevity in tough environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Shaft Seals Category

CHOPPER & MAIN SHAFT SEAL FOR RMG

Price 3500 INR / Piece

Minimum Order Quantity : 10 Pieces

Shape : Round

Application : Rapid Mixer Granulator (RMG) Main/Chopper Shaft

Tolerance : 0.05 mm

Style : Other, Rotary Shaft Seal

Multi Spring Seal

Price 3500 INR / Piece

Minimum Order Quantity : 10 Pieces

Shape : Round

Application : Pumps, Compressors, Mixers, Agitators

Tolerance : 0.05 mm

Style : Mechanical Seal

Mechanical Metal Bellow Seals

Price 18000 INR / Pack

Minimum Order Quantity : 10 Packs

Shape : Round

Application : Industrial Pumps, Chemical Processing, Petrochemical Industry

Tolerance : 0.01 mm

Style : Other, Mechanical

Mechanical Reactor Seals

Price 4200 INR / Piece

Minimum Order Quantity : 1 , , Piece

Shape : Round (Standard Reactor Seal Configuration)

Application : Chemical reactors, pharmaceuticals, petrochemicals, and agitators

Tolerance : 0.01 mm

Style : Other, Cartridge, Double, Single, Balanced/Unbalanced

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS