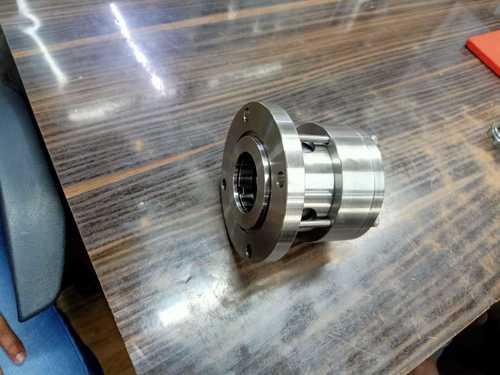

Mechanical Metal Bellow Seals

Price 18000 INR/ Pack

Mechanical Metal Bellow Seals Specification

- Tolerance

- 0.01 mm

- Material

- Stainless Steel, Carbon, Silicon, Rubber

- Style

- Mechanical

- Shape

- Round

- Application

- Industrial Pumps, Chemical Processing, Petrochemical Industry

- Pressure Range

- Up to 25 bar

- Surface Finish

- Ra 0.2 m

- Rotational Speed

- Up to 3000 RPM

- Corrosion Resistance

- High

- Spring Type

- Multi convolution bellow

- Installation

- Easy to install and dismantle

- Seal Faces

- Carbon, Ceramic, Tungsten Carbide, Silicon Carbide

- Product Type

- Mechanical Metal Bellow Seal

- Suitable Media

- Water, Oil, Acids, Chemicals

Mechanical Metal Bellow Seals Trade Information

- Minimum Order Quantity

- 10 Packs

- Supply Ability

- 100 Packs Per Month

- Delivery Time

- 2-5 Days

About Mechanical Metal Bellow Seals

We hold expertise in offering our valuable clients a wide range of Metal Bellow Seals, which is widely used in numerous applications such as vacuum interrupters, mechanical seals, pressure gauges, sensors and valve sealing etc. Precisely made from optimum quality metals in compliance with the set industry standards, these seals are tested on various parameters for ensuring their optimum quality. The offered seals are available in different dimensions according to the needs of clients. Further, these Metal Bellow Seals are greatly admired for their features like durability, dimensional accuracy, tough construction, rust resistance and high tensile strength.

Optimal Sealing Performance

Designed to handle a wide variety of challenging fluids, our mechanical metal bellow seals excel with water, oil, acids, and chemicals. The engineered surface finish (Ra 0.2 m) and precise tolerances help achieve superior leak-proof reliability, reducing maintenance frequency for pumps in chemical processing and petrochemical industries.

High Durability and Corrosion Resistance

Built from robust stainless steel and advanced sealing materials, these bellow seals resist corrosion, making them ideal for harsh industrial environments. The multi convolution bellow spring design withstands repetitive mechanical stress, while high-quality seal faces ensure longevity even at higher pressures and rotational speeds.

Efficient Installation and Maintenance

Engineered for simplicity, our mechanical metal bellow seals feature easy installation and dismantling procedures. Their precise dimensions ensure compatibility with standard equipment, enabling quick replacement and minimal downtime for your critical industrial systems.

FAQs of Mechanical Metal Bellow Seals:

Q: How are mechanical metal bellow seals installed and dismantled?

A: Mechanical metal bellow seals are designed for user-friendly installation and disassembly. Their round, mechanical shape and precise tolerances (0.01 mm) enable an accurate fit in pump housings or equipment, simplifying both the initial setup and any future maintenance procedures.Q: What types of media are suitable for these metal bellow seals?

A: These seals are highly versatile and suitable for a broad spectrum of fluids, including water, oil, acids, and various chemicals. Their corrosion-resistant materials ensure reliable sealing even when exposed to aggressive or hazardous fluids commonly found in industrial and chemical processing applications.Q: When should I use a mechanical metal bellow seal in my equipment?

A: Use these seals when you require leakage prevention in systems operating at pressures up to 25 bar and rotational speeds up to 3000 RPM. They are ideal for industrial pumps, chemical processing units, and petrochemical machinery where high performance and corrosion resistance are crucial.Q: Where are mechanical metal bellow seals commonly used?

A: These seals are widely utilized in industrial pumps, chemical and petrochemical plants, and processing equipment across a variety of manufacturing sectors in India. Their robust design makes them the preferred choice for applications involving aggressive media and high-demand environments.Q: What is the benefit of the multi convolution bellow spring design?

A: The multi convolution bellow spring offers enhanced flexibility and resilience, ensuring consistent sealing pressure even under fluctuating operating conditions. This design minimizes wear, extends seal life, and helps maintain stable performance in both standard and challenging industrial settings.Q: How does the surface finish and material choice affect seal performance?

A: A fine surface finish (Ra 0.2 m) improves sealing effectiveness by reducing friction and wear on the seal faces. Using quality materials like stainless steel, carbon, silicon carbide, and rubber enhances overall durability, corrosion resistance, and compatibility with a wide range of chemical media.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mechanical Shaft Seals Category

SINGLE CARTRIDGE WITH BEARING SEAL

Price 1000 INR / Piece

Minimum Order Quantity : 10 Pieces

Shape : Round

Style : Other, Single Cartridge

Tolerance : 0.01 mm

Application : Pumps, Mixers, Compressors

Mechanical Ceramic Seal Rings

Price 400 INR / Piece

Minimum Order Quantity : 10 Pieces

Shape : Round

Style : Other, Ring

Tolerance : 0.01 mm

Application : Mechanical seals for pumps, compressors, agitators, and mixers

Slurry Seals

Price 1500 INR / Piece

Minimum Order Quantity : 10 Pieces

Shape : Round

Style : Other, Balanced and Unbalanced

Tolerance : 0.05 mm

Application : Slurry Transfer Pumps, Mineral Processing, Chemical Handling

Mechanical Reactor Seals

Price 4200 INR / Piece

Minimum Order Quantity : 1 , , Piece

Shape : Round (Standard Reactor Seal Configuration)

Style : Other, Cartridge, Double, Single, Balanced/Unbalanced

Tolerance : 0.01 mm

Application : Chemical reactors, pharmaceuticals, petrochemicals, and agitators

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS